Introsys

Especialistas em Automação Industrial

Liderar, de forma sustentada, o mercado mundial da automação industrial, estabelecendo relações duradouras e de confiança com os nossos clientes.

Criar, através de profissionais altamente qualificados, soluções de automação e robótica adaptadas a cada cliente, valorizando a inovação e a melhoria contínua dos seus processos e produtos.

A Inovação, a Colaboração, o Compromisso e a Alegria são os pilares que desde 2002 sustentam o nosso percurso.

01

Inovação

Apostamos na Inovação enquanto fator determinante para a nossa competitividade e sustentabilidade.

02

Know-How

Os mais de 20 anos de experiência em projetos nacionais e internacionais permitem-nos oferecer robustez nos produtos que fornecemos para os vários setores industriais.

03

Diferenciação

Trazemos para as diversas indústrias de manufatura a experiência adquirida num setor com elevados níveis de exigência – indústria automóvel, aliada ao conhecimento desenvolvido nos mais recentes sistemas da indústria 4.0.

PRODUTOS

Soluções de Automação Industrial Sustentáveis

SERVIÇOS

Pela sustentabilidade da sua empresa e dos seus produtos

Otimize a sua empresa com as soluções costumizadas

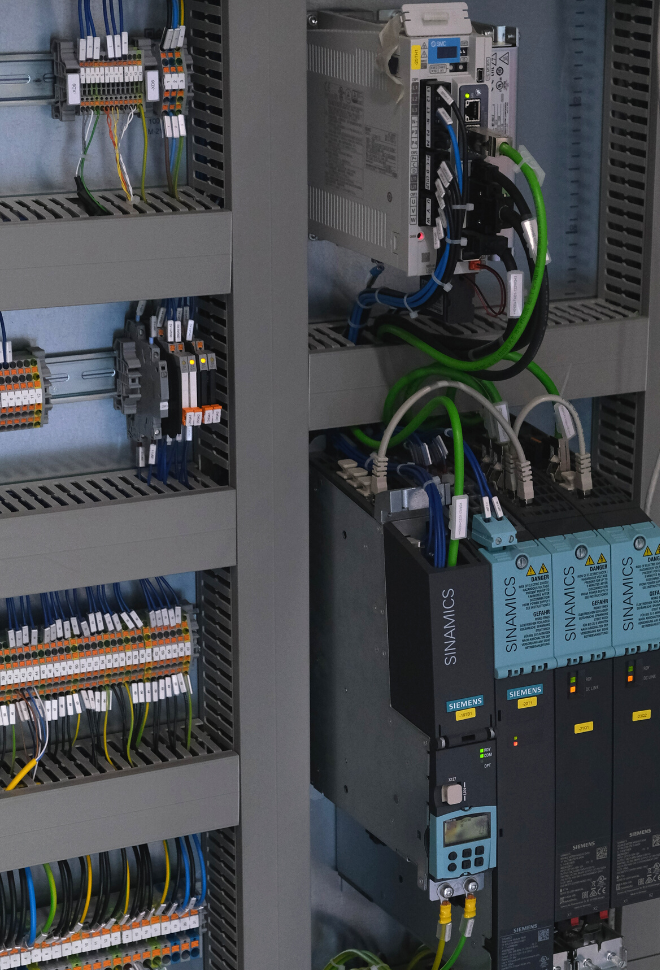

Industria 4.0

Retrofitting |

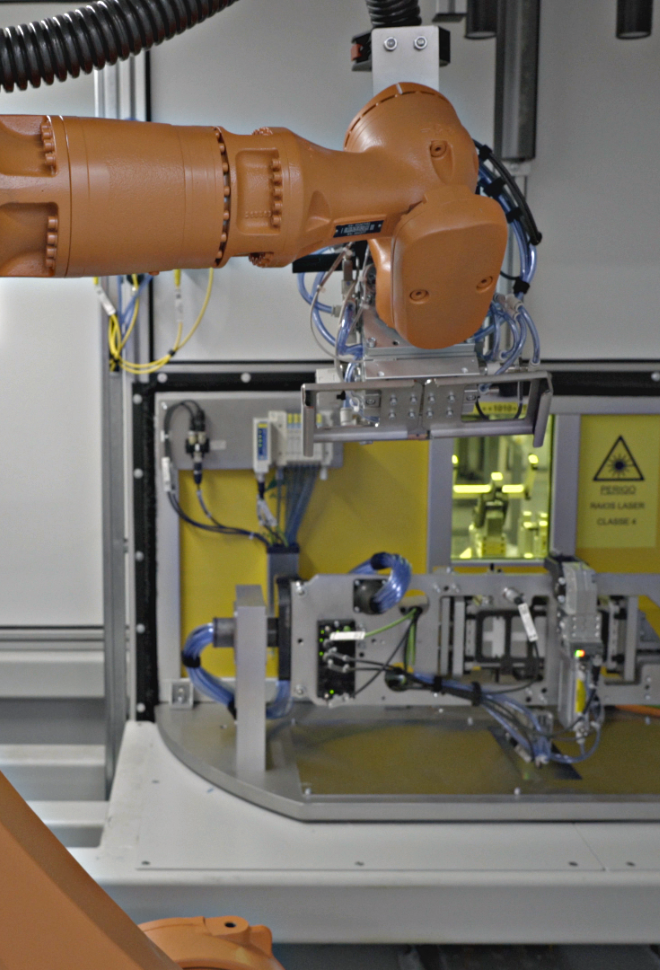

Soluções robotizadas – Projetos de Engenharia chave na mão

PORTEFÓLIO

Projetos desenvolvidos em diversas áreas,

adaptados a cada realidade

NOTÍCIAS

Fique a par das

novidades

Junte-se à nossa equipa

Descubra as vagas em aberto ou faça a sua candidatura espontânea.

Formação certificada

Conheça a Introsys Training Academy e descubra mais sobre as formações!